Knurled brass nuts

Knurled brass nuts are thread inserts, which can be mold into plastic. At HoverMower they are used at all places which might be screwed and unsrewed multiple times. All Covers and lids are equipped with them. This way, it is easy to open a cover multiple times during build without to wear out threads, like self-tapering screws will do. Also they are used on places where it is hard to insert common hex nuts.

For details about which kind ob brass nuts are used, please refer to BOM.

Instructions

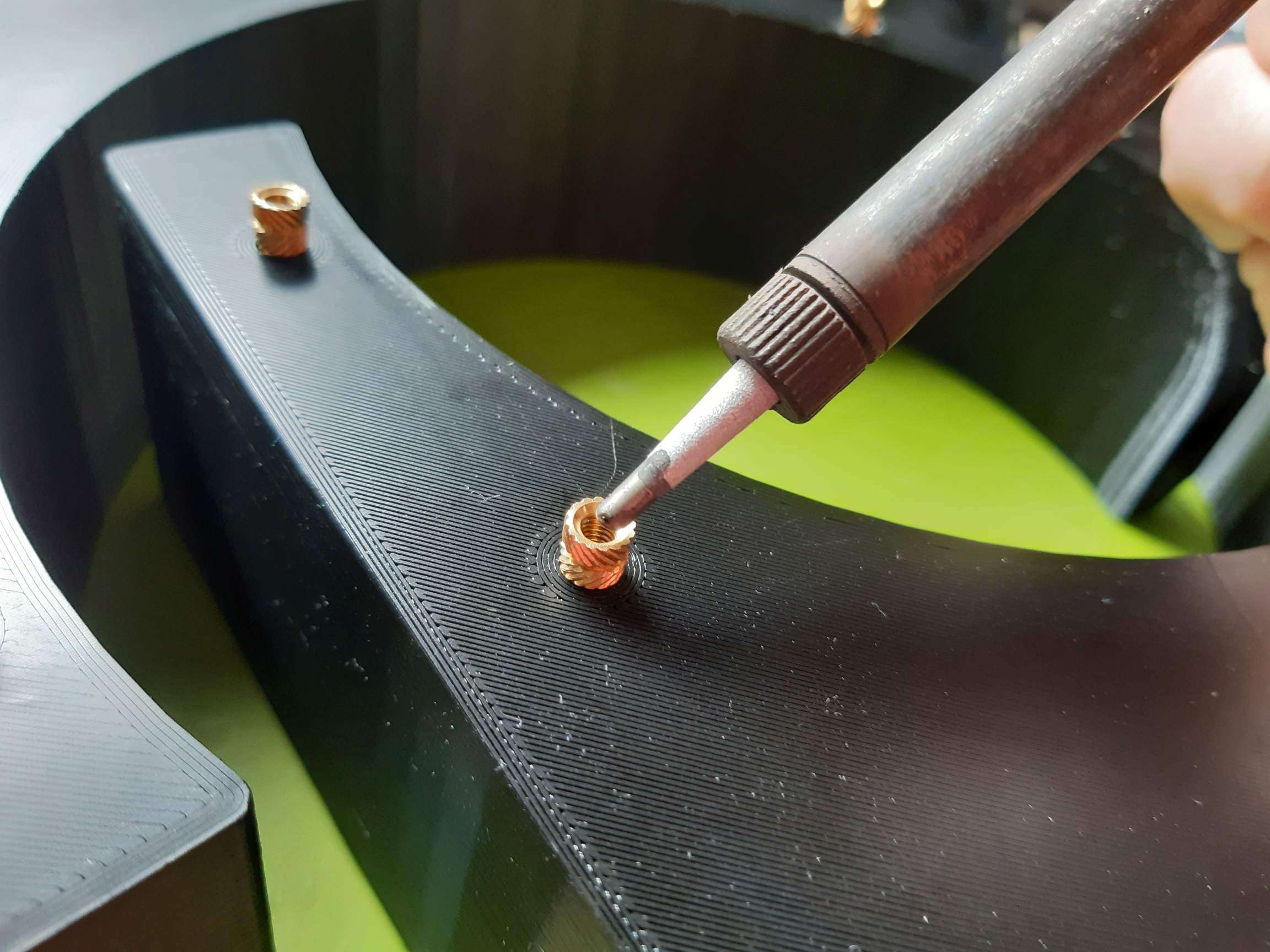

You need a soldering iron with an large tip. There are also special soldering tips available for molding brass nuts into plastic. First of all, heat up your soldering iron to an temperature above melting point of material you use. For example, PETG should be at least 250°C.

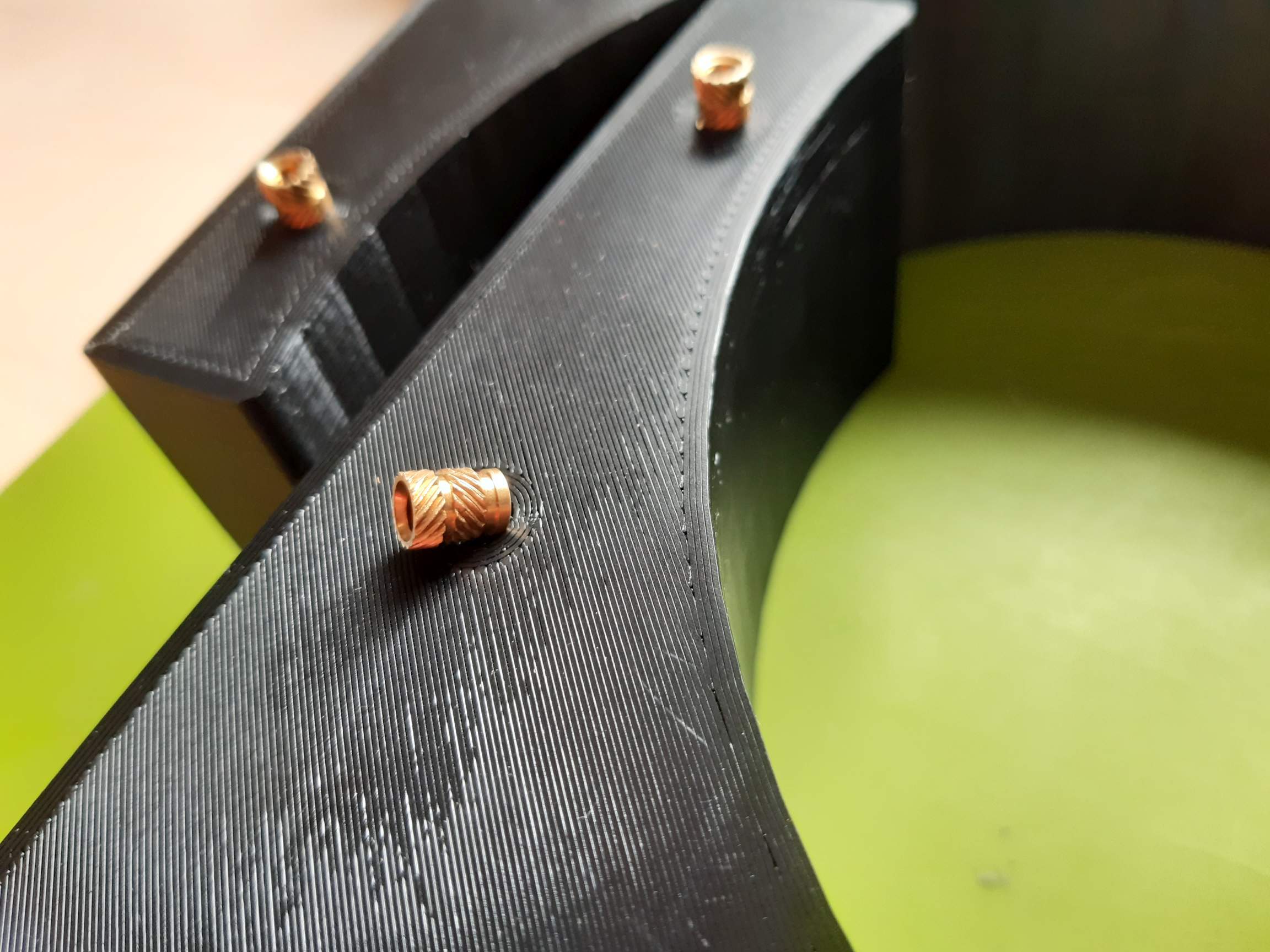

Now place the brass nuts into the holes. There is a groove at one side of the nuts. This must be inserted first.

Next, place the tip of soldering iron on the brass nut and wait for heat up.

Press gently until the nut is flush with the surface

It should look like this when finished. Please let it cool down before assembly. Please also be patient not to burn your fingers. The images here shows the wheel arches.